Qingdao Shende has been deeply engaged in the plastics machinery industry for decades and is a leading example of China's intelligent manufacturing in the field of piping equipment. The company has established a research and development team composed of experts in mechanical engineering and materials science, collaborating with universities to overcome the technical difficulties in double-wall corrugated pipe production. The independently developed multi-layer co-extrusion system precisely controls the blending ratio of HDPE and PP raw materials, increasing the ring stiffness of the corrugated pipe by 20%. The innovative corrugation forming mold, made of a special alloy, has a service life 1.5 times that of conventional molds. An intelligent wall thickness monitoring system adjusts extrusion parameters in real time to ensure that the pipe wall thickness tolerance does not exceed ±0.5mm. These technologies, embodying the ingenuity of Chinese engineers, ensure that even used production lines possess the core capability for efficient production.

Qingdao Shende has extremely stringent standards for the quality of used equipment. Every recycled HDPE-PP 600 double-wall corrugated pipe production line undergoes a rigorous "three inspections and three repairs" process: the inspection team uses ultrasonic flaw detectors to identify hidden damage in the screw and barrel, and a dynamic pressure tester to verify the stability of the extrusion system. Technicians perform laser cladding repairs on worn parts, replace imported seals and bearings, and upgrade the PLC control system. Finally, a 72-hour continuous trial run is conducted, during which the produced corrugated pipes must pass 12 tests, including ring flexibility and impact strength, before they can be delivered. This process enables the corrugated pipes produced by the used production line to withstand external pressures of 8kN/m², fully meeting the stringent requirements of municipal engineering projects.

In terms of price, Qingdao Shende's used production line offers a remarkable advantage. While a new HDPE-PP 600 double-wall corrugated pipe production line can cost millions, the cost of used equipment is reduced by over 60%. After purchasing this equipment, a municipal pipe manufacturer not only reduced its equipment investment by nearly half but also used the savings to expand its raw material reserves, increasing its monthly production capacity by 30%. Leveraging lower costs to increase production capacity allows companies to quickly gain an advantage in market competition.

After-sales support is another key strength of Qingdao Shende. Our professional after-sales team promises 24-hour response and on-site service within 48 hours. Upon arrival, our engineers will oversee the entire installation and commissioning process, providing three days of free operator training. During daily production, our IoT system remotely monitors equipment operating status, providing early warning of potential failures. Our spare parts warehouse stocks over 200 commonly used parts, offering nationwide 48-hour delivery to minimize downtime.

Qingdao Shende's used HDPE-PP 600 double-wall corrugated pipe production line leverages the expertise of Chinese manufacturers, ensuring quality through rigorous quality inspections, offering affordable pricing, and eliminating concerns through comprehensive after-sales service. Its stable and reliable performance allows companies to efficiently produce high-quality corrugated pipe while controlling costs, easily meeting market challenges, and ushering in a new era in pipeline production.

1. Equipment Function (This equipment uses two conical twin-screw extruders to produce HDPE/PP double-wall corrugated pipe)

1.1 Basic Equipment Technical Parameters

|

Pipe material range: ID200-600 |

Production specifications: 200, 300, 400, 500, 600 |

|

Maximum Production Capacity |

8 tons/day (based on ID400 x 25 days x 10 months = 1,750 tons/year) |

|

Actual Water Supply |

1.5 m3/h |

|

Water consumption of production line |

6 m3/h (water quality salt content <150ppm, temperature 20℃) circulating water |

|

Ambient temperature |

0-45 ℃ |

|

power supply |

3-phase + N + G, (380V + 5% 50Hz) |

|

Production line installed capacity |

About 274KW |

|

Actual power consumption of the production line |

About 219KW |

|

Using resin |

HDPE80, PE100 or PPB/PPR pipe materials |

|

Operation direction |

Right to left |

|

Device color |

Creamy white or color swatch provided by customer |

|

Production line length, width and height |

25m*4m*2.8m |

2.1 Double-wall corrugated pipe production line (Note: does not include cutting machine)

|

Serial Number |

Device Name |

Quantity |

Remark |

|

1 |

TSZJ80/156 Cone Twin Extruder |

1 set |

Main motor power 55KW (outer wall main unit) |

|

2 |

TSZJ80/156 Cone Twin Extruder |

1 set |

Main motor power 55KW (inner wall main engine) |

|

3 |

mold rack |

1 set |

|

|

4 |

Gas control cabinet system |

1 set |

|

|

5 |

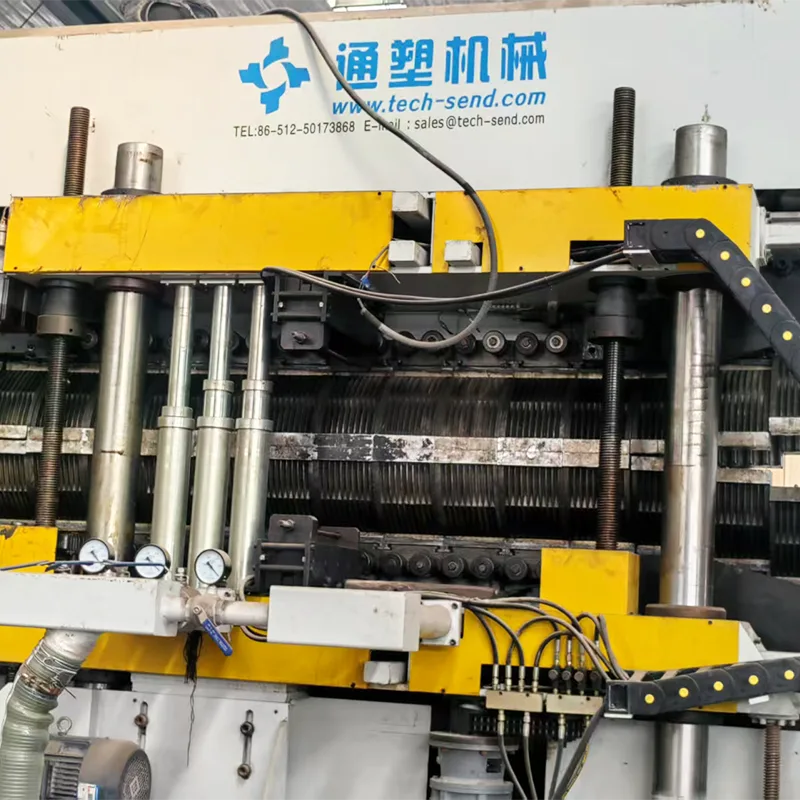

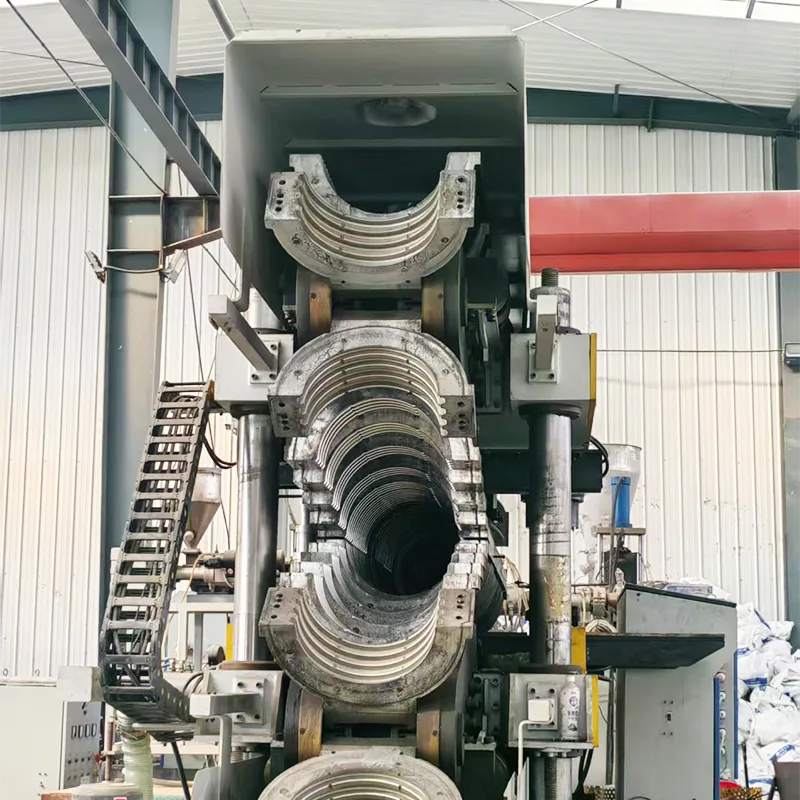

SBG-600 forming machine |

1 set |

Production range ID200-600mm |

|

6 |

Vacuum system |

1 set |

Vacuum pump 37KW 1 set |

|

7 |

Pipe turning rack |

1 set |

With electronic weighing device |

|

8 |

Electrical control system |

1 set |

Siemens PLC control |

Thanks to its optimized screw and bimetallic design, the extruder offers the following advantages: high plasticization rate, uniform melt, and continuous and stable production. The high-performance gearbox has been optimized to reduce noise. The drive motor is a Jiangsu Beide AC motor with a power of 55 kW/55 kW. The barrel temperature is controlled in four zones and heated by a ceramic air-cooled heating coil. The alarm system includes an audible and visual alarm. The AC inverter is a well-known brand, such as ABB or Park. Its main function is to provide stepless speed regulation of the main machine from zero to rated speed. The speed regulator has a built-in high-speed CPU, which provides rapid detection and protection functions. The core components of the logic control system are a Siemens PLC with expansion modules and a Siemens 10.7 color screen. The temperature control module monitors and controls the process temperatures of the barrel and mold. The speed control module regulates the speed of the molding machine and two main machines. The PLC allows for the setting, storage, correction, alarming, monitoring, and display of operating conditions such as main machine speed, melt pressure, melt temperature, barrel zone temperatures, mold temperature, and molding speed.

1) Two TSJZ80/156 conical twin extruders (one each for the inner and outer extruders)

|

Parameter name |

Technical Parameters |

|

|

Extruder |

Electrical control cabinet manufacturers |

Mainfrequency converter and feeding frequency converter: ABB or Park, contactor, circuit breaker, etc.: Suzhou Siemens |

|

Extrusion capacity (kg/hour) |

Guaranteed output of 260kg/h, committed to 300kg/h under good plasticizing conditions |

|

|

Overall dimensions (mm3) |

4235mmX1520mmX2450mm |

|

|

Machine weight (kg) |

4000kg |

|

|

Hopper taper |

10° |

|

|

The main power supply terminal adopts the form |

Three-phase four-wire system |

|

|

Temperature control curve form |

Temperature fluctuation self-tuning adjustment (PID type) |

|

|

Origin of temperature control gauges, pressure gauges, speed gauges, etc. |

Imported Siemens computer control |

|

|

Is there a pressure display? |

With melt pressure display |

|

|

Configuration of the die head and die head flange |

Bolted connections |

|

|

Operation console data display mode |

Mainly digital display |

|

|

Structural features that are superior to those of the same industry |

Good plasticization, large output, reasonable design, high precision, and use of high-quality components and parts made of high-quality materials, mainly self-made, good stability, easy to control,the main inverter uses ABB or Park. |

|

|

Screw |

Diameter (mm) |

80/156 |

|

Effective length (mm) |

1815 |

|

|

Quantity (roots) |

2 |

|

|

Meshing form |

Conical toothing |

|

|

Total torque (KN m) |

14.2 |

|

|

Speed (r/min) |

1~34.7 (different direction outward) |

|

|

Nitriding depth (mm) |

0.6~0.7 |

|

|

Can I eat crushed food? |

able |

|

|

Screw core heating method |

none |

|

|

Barrel |

Barrel form |

integral |

|

Heating method |

The barrel is air-cooled and has a dedicated stainless steel shell and cast aluminum electric heater |

|

|

Barrel heating section number (section) |

5 |

|

|

Heating power (kw) |

36 |

|

|

Temperature control range (℃) |

50~300 |

|

|

Number of barrel cooling sections (sections) |

3 |

|

|

Machine head connecting sleeve |

3Cr13 stainless steel, hard chrome plated surface treatment, internal confluence |

|

|

Cooling control |

4X0.55Kw fan control |

|

|

Cooling medium |

Air |

|

|

Screw and barrel origin |

Zhoushan |

|

|

Screw and barrel quality assurance measures |

Provide test blocks and test reports. Calcium carbonate 50% screw and barrel warranty for 6 months. |

|

|

Nitriding depth (mm) |

0.6~0.7 |

|

|

Transmission reduction system |

Main drive motor power (kw) |

55 |

|

Main drive motor working mode |

Three-phase asynchronous motor, connected to the reduction gearbox through a coupling |

|

|

Main drive motor speed (r/min) |

300~1500 |

|

|

Gearbox type |

Gear reduction, using hardened tooth surface and helical tooth surface combination |

|

|

reduction gear |

Carburized and ground teeth, made of 20CrMoTi |

|

|

Distribution gearbox type |

The two distribution shafts are driven by super-conical rotating bevel gears. |

|

|

Main drive motor speed regulation mode |

AC variable frequency speed regulation, the inverter adopts ABB or Park company |

|

|

quantitative feeding system |

Feeding method |

Quantitative feeding (twin screw feeding) |

|

Feed screw speed (r/min) |

0.5~50 |

|

|

Motor power (Kw) |

1.5 |

|

|

Motor speed (r/min) |

10~1500 |

|

|

Motor speed regulation mode |

AC variable frequency speed regulation |

|

|

Motor working mode |

Three-phase asynchronous motor, directly connected to the reducer |

|

2) Molding machine parameters:

| Molding Machine |

Dimensions |

6400mm × 3350mm × 3850mm -4200mm (length * width * height) |

|

Guide column center distance |

1065 mm |

|

|

Upper guide rail travel |

Upper guide rail travel greater than 500 mm |

|

|

Longitudinal forward and backward stroke |

2400mm (electric power 1.5KW) |

|

|

Left and right movement |

50 mm |

|

|

Production range |

Online flaring is double-wall flaring, and the maximum inner diameter of the produced pipe is ID600 |

|

|

Maximum line speed without load |

Speed range 0.3-5 m/min, maximum no-load speed 5 m/min |

|

|

Molding machine up and down movement accuracy |

The overall vertical movement accuracy of the molding machine is ±0.05 mm (electric power 1.5KW, and can move up and down independently) |

|

|

Molding machine left and right movement accuracy |

The overall left and right movement accuracy of the molding machine is ±0.05 mm |

|

|

Number of forming vacuum sections |

Four-stage vacuum (vacuum pump 37KW, pumping rate 40m3/H, speed 1460 rpm, ultimate pressure 2000PA) |

|

|

Module running rail |

The module running guide rail material is 38CrMoAlA, the surface nitriding treatment hardness reaches HRC62 or above, and it is processed by guide rail grinder, and the straightness after processing is ±0.01 |

|

|

mold base |

The die base material is 38CrMoAlA with surface nitriding treatment and hardness reaching HRC50--55 |

|

|

Forming machine front and rear moving guide rail |

The molding machine's front, back, left, and right moving guide rails use linear bearings |

|

|

Molding machine hydraulic system |

The hydraulic system of the molding machine adopts the Sino-Italian joint venture atos and Limoda lubrication system (automatic guide rail lubrication system, oil pump motor power 1.1KW) |

|

|

Molding machine pneumatic system |

The pneumatic components of the molding machine, the reversing valve and the pressure regulating valve are imported from SMC or joint ventures (mainly used for online expansion) |

|

|

Molding machine main motor |

The main motor of the molding machine is 7.5KW and adopts AC motor, andthe speed regulator adopts ABB or Park products. |

|

|

Molding machine gearbox |

The gearboxes of the forming machines are all made of high quality, with hardened tooth surface and arc tooth surface for transmission, high transmission accuracy, stable operation, large transmission torque, low noise and long service life. |

|

|

Molding machine cooling method |

Molding machine module cooling adopts air cooling, six 0.5KW fans |

3) Unloading rack parameters:

|

Unloading platform |

Unloading platform structure |

Steel skeleton structure |

|

Unloading platform length |

6000 mm |

|

|

Unloading rack control method |

Pneumatic automatic turning |

4) Spare parts:

|

Serial number |

Spare part name |

Number of spare parts |

Spare part code (model) |

|

1 |

Porcelain plug |

10 items |

|

|

2 |

High temperature wire |

50 meters |

|

|

3 |

Thermocouple |

10 items |

|

|

4 |

contactor |

4 items |

|

|

5 |

breaker |

4 items |

|

|

6 |

vacuum gauge |

4 items |

|

|

7 |

pressure regulating valve |

2 items |

|

|

8 |

Molding machine die base roller |

4 items |

|

Address

No. 68, Pingcheng West Road, Jiaoxi Industrial Park, Jiaozhou, Qingdao City, Shandong Province, China

Tel