In the competitive world of plastic profile manufacturing, the right equipment is more than just a purchase; it's a strategic investment. It determines your product quality, operational efficiency, and ultimately, your profitability. While a new machine might seem like the default choice, high-quality used plastic profile machines offer a smarter, more economical way to achieve superior production without a significant capital investment. Qingdao Shende Plastic Machinery Co., Ltd. leverages decades of engineering expertise in China's manufacturing hub to meticulously refurbish and upgrade our used machines, ensuring their reliability and precision rival that of new equipment.

Substantial Cost Savings: Compared to purchasing new equivalent equipment, purchasing a used plastic profile machine can save you 30-50% or more. This frees up valuable funds for other areas like raw material inventory, marketing, or R&D.

Proven Technology: Our used equipment is built on a proven, stable platform. Any potential teething issues have been identified and addressed, ensuring reliable power from day one. Faster Return on Investment: A lower initial investment allows for a faster return on investment, increasing your company's financial flexibility.

Shorter Lead Times: We maintain a stock of professionally refurbished equipment, significantly reducing wait times compared to ordering new, custom equipment.

Material Handling: They expertly handle PVC compounds containing additives such as ACRs (processing aids) and CPEs (impact modifiers).

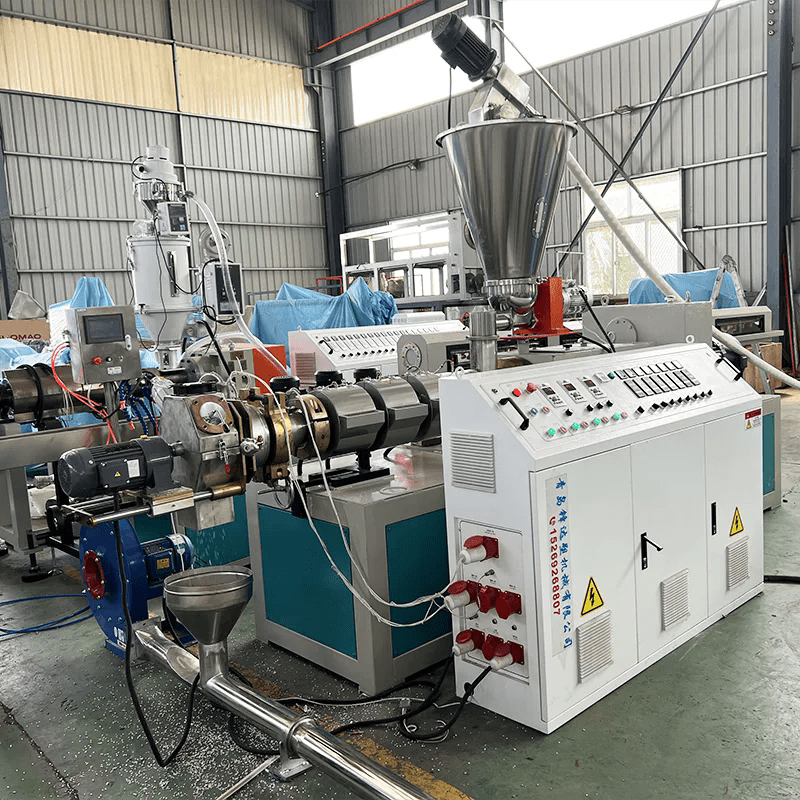

Extrusion Precision: The high-efficiency screw ensures uniform plasticization without degradation, while precise multi-zone temperature control minimizes fluctuations, preventing defects such as bubbles, scorching, and dimensional instability.

End Product: The end product features excellent impact resistance, a smooth surface finish, and consistent geometry for use in door, window, or furniture applications.

1. What is the typical condition and remaining service life of Shende's used plastic profile machines?

We do not sell "as is" used machines. Every machine in our inventory undergoes a rigorous multi-point inspection and refurbishment process. This includes a mechanical overhaul (screw and barrel inspection, gearbox repair), an electrical system refresh (replacement of worn parts, drive testing), and calibration of all systems. ShenDe used machines are in excellent working condition and, if properly maintained, can provide years of reliable service, typically exceeding 70-80% of their designed life.

2. How does the performance of a used machine compare to a new one?

In most standard applications, a professionally refurbished used machine from a reputable manufacturer like ShenDe performs comparable to a new one. The key difference is cost. We replace or refurbish all wear parts, ensuring performance specifications match the original standards. We also provide comprehensive after-sales support, including installation instructions, operator training, and a readily available spare parts inventory. You're not just buying a machine; you're acquiring a long-term partner.

3. Can the machine be customized to our specific profile or material?

Yes, to a large extent. While the extruder mainframe is fixed, many components are adjustable. We can source and install specific calibration tables, sizing plates, and downstream equipment (haul-offs, cutters) to accommodate your profile cross-section and material. We also adjust screw speeds, temperature profiles and draw settings during commissioning to optimize the line for your specific formulation, whether it’s PVC, UPVC or polycarbonate.